From Concept to Precision Reality

At SRI VIJAYALAXMI CNC TECH, our Design & Development division plays a pivotal role in transforming client requirements into reliable engineering solutions. We work closely with our customers from the initial concept stage, offering design support, feasibility analysis, and technical consultation to ensure that every component is optimized for performance and cost-effectiveness. With advanced CAD/CAM software, skilled engineers, and a strong focus on innovation, we specialize in developing prototypes that can be seamlessly scaled to full production. Our expertise covers complex machining requirements for industries such as Automotive, Defence, Aerospace, Energy, Marine, and Oil & Gas, where precision and durability are critical. By combining creativity with state-of-the-art CNC and VMC technology, we ensure that every design not only meets but exceeds client expectations. At the heart of our approach lies a commitment to quality, timely delivery, and continuous improvement — making us a trusted partner for mission-critical product development.

Our Core Design Capabilities

At SRI VIJAYALAXMI CNC TECH, our design expertise ensures that every project is engineered with precision, efficiency, and innovation. We combine advanced software, skilled engineers, and industry know-how to deliver solutions tailored to client needs.

-

Conceptual Design Support – Assisting clients in refining ideas into feasible engineering models.

-

CAD/CAM Expertise – Using advanced software for accurate and efficient design outputs.

-

Prototype Development – Building and testing prototypes to validate design performance.

-

Product Optimization – Enhancing designs for durability, functionality, and cost-effectiveness.

-

Industry-Specific Solutions – Customized designs for Automotive and Aerospace applications.

Development Process

At SRI VIJAYALAXMI CNC TECH, our development process is structured to ensure precision, efficiency, and customer satisfaction at every stage.

-

Requirement Analysis – Understanding client needs and technical specifications.

-

Concept & Feasibility – Creating design concepts and evaluating practicality.

-

Prototype Creation – Developing prototypes to validate design and performance.

-

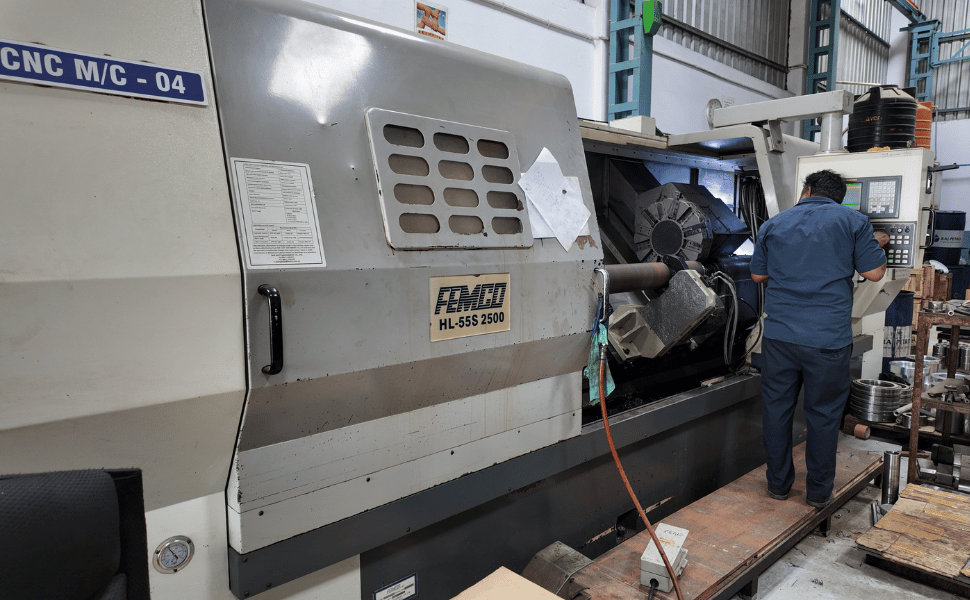

Precision Manufacturing – Using CNC/VMC technology for accurate production.

-

Testing & Quality Checks – Ensuring components meet global standards.

-

Final Delivery – Supplying reliable, ready-to-use solutions on time.

Why Choose SVCT for Design & Development?

At SRI VIJAYALAXMI CNC TECH, we combine innovation, expertise, and technology to deliver world-class design and development solutions that truly stand out.

-

👨🔧 Experienced Team – Skilled engineers with hands-on industry expertise.

-

🖥️ Advanced Tools – Latest CAD/CAM software ensuring accurate designs.

-

🔄 End-to-End Support – From concept validation to prototype and production.

-

🌍 Industry Versatility – Trusted across Automotive, Defence, Aerospace, Energy & Marine.

-

✅ Quality Commitment – ISO-certified processes for precision and reliability.